Increased efficiency characterizes our modern world, and innovation is one of the key trends of today’s world which has impacted many industries including the fabrication industry. Fabrication processes do not differ, but one technology that is changing the whole picture is the use of lasers in laser cutting of sheet metals. Moreover, their products’ laser cutting construction fabrication design and detailing is undergoing applicability. Significantly enhancing cost-efficiency, productivity, and precision, this technology had done too much since it’s inception.

The Evolution and Benefits of Sheet Metal Laser Cutting

The steel fabrication industry is constantly improving from primitive methods of cutting and folding. Through the ages, manufacturers heavily depended on a manual Method of cutting, Mechanical Shearing, punching, alongside with other processes which were slow and tedious. Nevertheless, the introduction of industrial daily use tools and appliances has impacted greatly to the industry, with the Electric sander, and the Laser Metal Cutting nip saw laying ground for laser cutting of metals. After around two decades, technology saw the introduction of methodical phase-shift machines with the capability of intricate carving and withdrawing depths and oven triggered heaters. These bear exploitative benefits in contrast to laser cutting. The computers inclusive of CAD and anterior models cut fabrication efficiency exponentially, allowing metal manufacturing firms to be able to manufacture complex fragments without quality degradation, while lessening waste and enhancing working periods.

Instruments like lasers have now been integrated into the manufacturing process and this industry’s ability to deliver products to markets has increased dramatically. Perhaps the most distinguishing characteristics of lasers as compared to traditional machining rests on the aspects of speed and precision. Manufacturers can attain complex configurations with tolerances exceeding precision of ±0.1mm. That soaring level of accuracy is indispensable to the medical devices and electronics industries. In addition to the precision, the time efficiency lasers offer and the elimination of many steps in the process along with tool substitutions results in more time saved.</br>Laser cutters also have significant advantages in cost efficiency. Resources required are drastically reduced along with the high productivity from the saved steps. One other remarkable feature of laser cutting is its vast range of materials it can work with. As it is able to cut titanium, copper, aluminum, stainless steel, carbon steel, and even brass, manufacturers won’t need to change a remarkable amount of their equipment. Lasers also appeal from a sustainable fabrication perspective, generating significantly less waste, consuming less energy than other methods and ultimately producing fewer emissions.

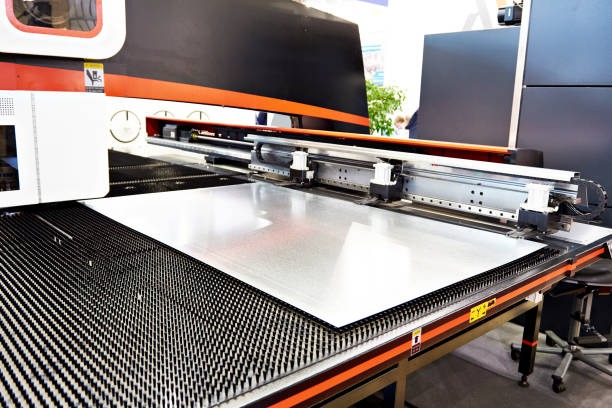

How Sheet Metal Laser Cutting Works

The cutting of sheet metals by lasers is done using a highly focused laser beam which melts, vaporizes, or burns the materials away with extreme precision. The entire process utilizes CNC systems, which provide precision, accuracy, and repeatability throughout the process. In the industry, three key categories of laser cutting technologies can be found: CO2 lasers, which are the go-to for non-metallic materials and certain metals; fiber lasers, which are the most popular brands for almost anything that needs to cut to metals, for example, aluminum and stainless steel, as they are extremely energy efficient; and those used for deep penetration and sharp precision work, the Nd:YAG lasers. With these technologies, fabrication projects of various degrees of difficulty could be accomplished from construction, automotive, to aerospace. It has become a common fact that most automation and control in processes have been created through the help of technology which allows for the combination of speed and precision.

The Application of Sheet Metal Laser Cutting Technology in Different Fields

Different industries benefit from the application of sheet metal laser cutting as it helps manufacturers to make intricate parts with great detail. Within the automotive industry, laser cutting is frequently employed in the production of car body panels, exhaust pipes, and gas tank structural components because it allows mass production while maintaining good quality. This technology is also beneficial to the aerospace and defense industries because they require components to be precise, strong, and lightweight which laser cutting provides. Laser cutting is essential in the fabrication of delicate and complex pieces such as circuit boards and electronic enclosures used in consumer and industrial electrical devices for the electronics and electrical industry. Construction and architecture use laser cutting in creating decorative panels, structural frameworks, and other custom design pieces used in modern buildings which gives architects the opportunity to design appealing structures. The medical field also makes use of laser cutting in making sterile metal parts used in surgical instruments, implants, and even diagnostic equipment to ensure precision and repetitiveness. These are just a handful of the many uses for sheet metal laser cutting which makes it clear that it in turn increases productivity, precision, and creativity in countless industries.

Future Trends in Sheet Metal Laser Cutting

The fabrication sector is without a doubt poised to benefit from several technological advancements that are likely to arise in the upcoming years. They include the rise of automation – where processes such as human supervision is gradually being eliminated – as well as the onset of smart manufacturing systems which are defined by the presence of laser cutting machines that require little human input. These trends, accompanied with the integration of AI-driven features will also assist in determining the production processes that will guarantee the most profitable outcome in terms of overall costs and precision. The invention of new laser systems with a greater power to cut thicker materials at an increased speed is another trend that will also contribute to cost and time effectiveness. The combination of laser cutters and 3D printers also promises rapid advancement in prototyping and fabrication of complex components, angering hybrid manufacturing and enabling more innovative approaches. Advancements in sustainability measures are also pushing changes like refining the laser cutting technique with the goal of lowering energy requirements and improving material usage for greener manufacturing. The adoption of these methods guarantees enhanced competitiveness for businesses wanting to maintain robust modernization strategies in fabrication.

Conclusion

The use of sheet metal is cut and laser cut with a machine that has revolutionized the fabrication industry and saved both time and money, in addition to increasing efficiency. With the ability to handle complex designs and a wide range of materials, this technology has become a game-changer for sheet metal manufacturing companies worldwide. Laser cutting remains central to mass production today and as new technologies are developed in automation, AI, and ecological practices, it will continue to be the best way of cutting features on metals. By taking up such technology, companies not only increase their production, but they also position themselves strategically to outperform their competitors.